The Hidden Cost of Temperature Excursions—and How to Cut Exceptions Without Slowing Routes

Temperature excursions aren’t “events.” They’re operational debt.

Most ops teams don’t feel the pain of a temperature excursion at the moment it happens.

They feel it later—when diagnosis is delayed, a customer complains, when a specimen needs to be recollected, when a team spends hours arguing over what really happened, and when leadership asks why this keeps repeating.

And by then, the true cost has compounded across three dimensions:

| Time Cost | Service Cost | Reputation Cost |

| Dispatchers rework routes and prioritize re-deliveries Supervisors chase driver statements Ops analysts stitch together logs, emails, and screenshots Customer success spends hours doing damage control | Missed Turnaround-Time (TAT) commitments Delayed Lab diagnosis “Expedite culture” that trains teams to bypass SOPs to keep up | Customers stop trusting the lab capabilities Every future shipment is questioned New bids demand more proof, more audits, and more concessions |

The hard truth: excursions aren’t just thermal failures—they’re workflow failures. And exceptions become expensive when your process can’t answer three simple questions quickly:

- Did an excursion actually occur (or is it a false alarm)?

- Where did it happen—handoff, dwell, linehaul, delivery, or storage?

- What needs to change so it doesn’t repeat?

Why exception volumes grow even when you “add more monitoring.”

A common pattern: teams deploy sensors and alerts… and exception volume increases. Not because performance got worse, but because:

- Medical courier totes are not validated for operating conditions

- Alerts aren’t mapped to real operational thresholds

- Notifications aren’t actionable

- Data is trapped across devices, vendors, platforms, and spreadsheets

- “Investigation mode” becomes manual and slow

- Corrective actions aren’t standardized across assets, routes, and drivers

So you end up with exception noise, and operators start ignoring alerts—until a major customer escalation forces attention.

To fix this, you don’t need more monitoring.

You need an Exception Management System—a playbook that turns every alert into a fast, consistent decision.

The Exceptions Playbook: Cut Exceptions Without Slowing Routes

This playbook is designed for courier and logistics operators moving temperature-sensitive healthcare shipments—where every additional step creates friction.

Step 1: Classify exceptions into 3 levels (so every alert doesn’t become a fire drill)

Most operations treat all alerts equally. That’s how you get chaos.

Instead, define three operational categories:

Level 1: “Informational”

- Small deviations within a safe buffer

- Short-duration spikes (e.g., door open moment)

- No exposure risk based on profile/hold time

- Read it & skip. Be Informed.

Action: Auto-log and monitor (no human escalation)

Level 2: “Actionable”

- Risk is possible, but not confirmed

- Duration or severity needs review

- May require prevention action (reroute, reduce dwell, verify pack-out)

- Review it. Need attention if it repeats.

Action: Ops review within shift

Level 3: “Critical”

- Confirmed out-of-spec exposure

- Known lane vulnerability or repeated incident

- Customer visibility is required

- Resolve it. Need Actions to be taken.

Action: Escalate, generate a proof packet, and trigger CAPA (Corrective and Preventive Action)

Outcome: You stop treating 100 alerts like 100 emergencies. You engage people only where human judgment is needed.

Step 2: Move from “temperature alerts” to “workflow alerts”

A temperature chart alone rarely tells the story.

What matters operationally is where the excursion occurred in the workflow. Standardize exception tagging by the stage where it most likely happened:

- Collection / pickup

- Handoff / custody transfer

- Vehicle dwell / missed scan

- Linehaul / cross-dock

- Delivery delay / failed attempt

- Storage at facility / staging zone

Action: Every exception must map to a workflow stage in the first 15 minutes.

Outcome: Root Cause Analysis becomes faster because teams investigate the right part of the chain, not the entire journey.

Step 3: Set “investigation windows” so RCA (Root Cause Analysis) doesn’t drag for days

Exception investigations die when they stay open too long.

Set timeboxed standards:

- 15 minutes: classify (L1/L2/L3) with tag workflow stage

- 2 hours: confirm facts (timestamp, location, duration) and assign owner

- 24–48 hours: close RCA with a preventive action (not just a report)

Action: Treat exceptions like tickets with SLAs (Service Level Agreements), not open-ended debates.

Outcome: Faster closure, fewer repeat incidents, less time spent “finding the story.”

Step 4: Replace manual reconstruction with a “Proof Packet”

Your customers don’t want a narrative. They want proof.

A Proof Packet is a standardized, exportable bundle that answers:

- Where the shipment was (at any time and location)

- What the temperature exposure looked like (with thresholds)

- Whether the pack-out was correct

- Whether an SOP deviation occurred

- What corrective action was taken

Action: Standardize this packet so it’s generated the same way every time.

Outcome: Escalations become shorter, trust increases, and renewals get easier.

Step 5: Fix the top 20% of lanes causing 80% of exceptions

Most teams try to “improve everywhere.” That slows routes.

Instead, isolate exception hotspots:

- Lanes with high dwell variability

- Facilities with inconsistent staging practices

- Drivers with repeated custody/scan gaps

- Time windows where heat/cold exposure spikes

Action: Prioritize lane risk reduction, not universal changes.

Outcome: Exception reduction without adding steps to every route.

The goal isn’t zero excursions. It’s zero chaos.

Even best-run operations will face weather swings, traffic spikes, missed handoffs, and facility delays.

The difference is whether an excursion becomes:

- a minor ticket closed in hours, or

- a multi-day escalation with customer fallout

This is what modern exception management is really about: faster clarity, fewer repeats, and less friction.

Where Akuratemp fits: reduce noise, speed RCA, standardize prevention

Akuratemp® supports exception reduction in two complementary ways:

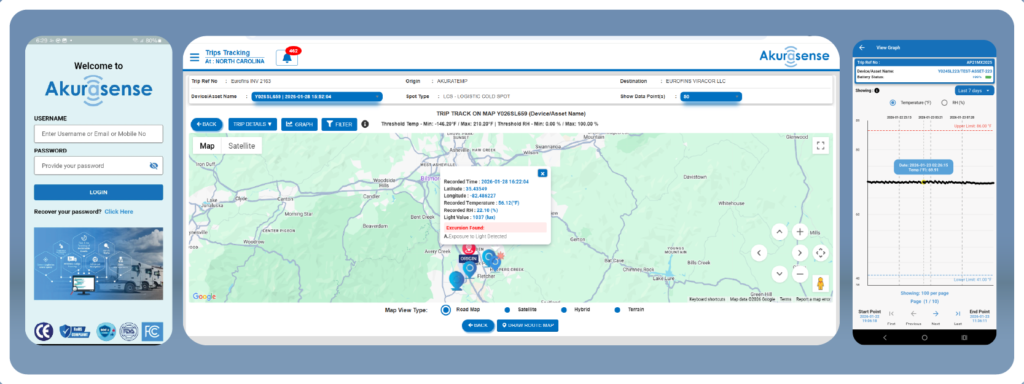

1) Akurasense™ monitoring and alerting that’s built for operations

Instead of turning every data point into noise, the Akurasesne™ platform helps you:

- Verify the readiness of the courier tote before trip initiation

- Maintain the courier tote chain-of-custody along the route

- Capture time, temperature, and location at each lockbox pickup

- Monitor the courier tote temperature in real-time along the route

- Trigger alerts that match your real thresholds and workflows

- Maintain audit-ready logs and reporting for customers

- Provides asset, in-transit & storage analytics for continuous improvement initiatives

2) Optymize® workflow standardization

Most exceptions repeat because SOPs vary across:

- Asset validation & handling

- Courier routes

- Courier discipline

- Collection sites

- Asset handoffs

Optymize® helps map current-state workflow for assets, couriers, and courier routes, identify risks and process waste, and implement validated assets with standardized processes to maximize conformance

The combined result: fewer exceptions, faster investigations, and fewer escalations—without slowing daily routes.

A practical next step: run a 14-day Exceptions Health Check

If you operate cold-chain routes, here’s a simple way to start without disruption:

Over 14 days run a pilot study by:

- Identifying the top 5 courier routes by exception volume

- Digitize assets on this route to capture time & location-stamped temperature data

- Analyze all asset data per courier route

- Analyze all asset data per asset type

- Develop corrective actions

Then apply the playbook to one route first. Improve there, then scale.

Schedule a conversation with Akuratemp, and together we’ll map your operations, close the gaps you can’t see today, and build a cold chain your customers can stand behind.