Patient to Lab Sample Shippers

Safely Transport In-Vitro Diagnostic (IVD) Specimen with Akuratemp Sample Shippers.

Sustainable temperature-controlled packaging solution

ISTA7D pre-validated sample shipping systems can help resolve the challenges of transporting time and temperature-sensitive biological samples. ISTA7D is a widely recognized industry standard test procedure for evaluating the performance of temperature-controlled packaging systems. By using these pre-validated systems, companies can have confidence in the performance and reliability of the packaging, and they can minimize the risk of temperature excursions ensuring sample integrity. Companies transporting time and temperature-sensitive biological samples can choose pre-validated systems that have already demonstrated compliance with the industry standards instead of conducting their own testing, which can be time-consuming and expensive, enabling them to focus on their core activities. By choosing systems that have undergone ISTA7D testing, companies can provide evidence of their efforts to ensure the safe transportation of biological samples, thus meeting the expectations of regulatory agencies and authorities.

The rigorous testing performed on ISTA7D pre-validated shipping systems provides assurance that the samples will remain within the specified temperature range during transportation, ensuring that the samples maintain their quality and efficacy upon arrival at their destination.

Akuratemp offers ISTA7D pre-validated multi-use sample shippers that are designed for reliability, sustainability, and end-to-end traceability in biological sample cold chain. Our patient to laboratory sample shippers are suitable for transporting 4 to 8 - 10ml Vials as frozen, refrigerated, or at controlled room temperature and validated for overnight to two day holdover time.

Akuratemp ATS 1

Multi-use sample shipper for 4x10ml vials with 12” x 8” x 8” external dimensions. Validated per ISTA7D testing to keep payload above +15°C for 48 hours in Winter.

Akuratemp ATS 3

Multi-use sample shipper for 4x10ml vials with 8” x 6.375” x 4.5” external dimensions. Validated per ISTA7D testing to keep payload frozen (-15°C to -5°C), refrigerated (+2°C to +30°C), or at CRT (+15°C to +25°C).

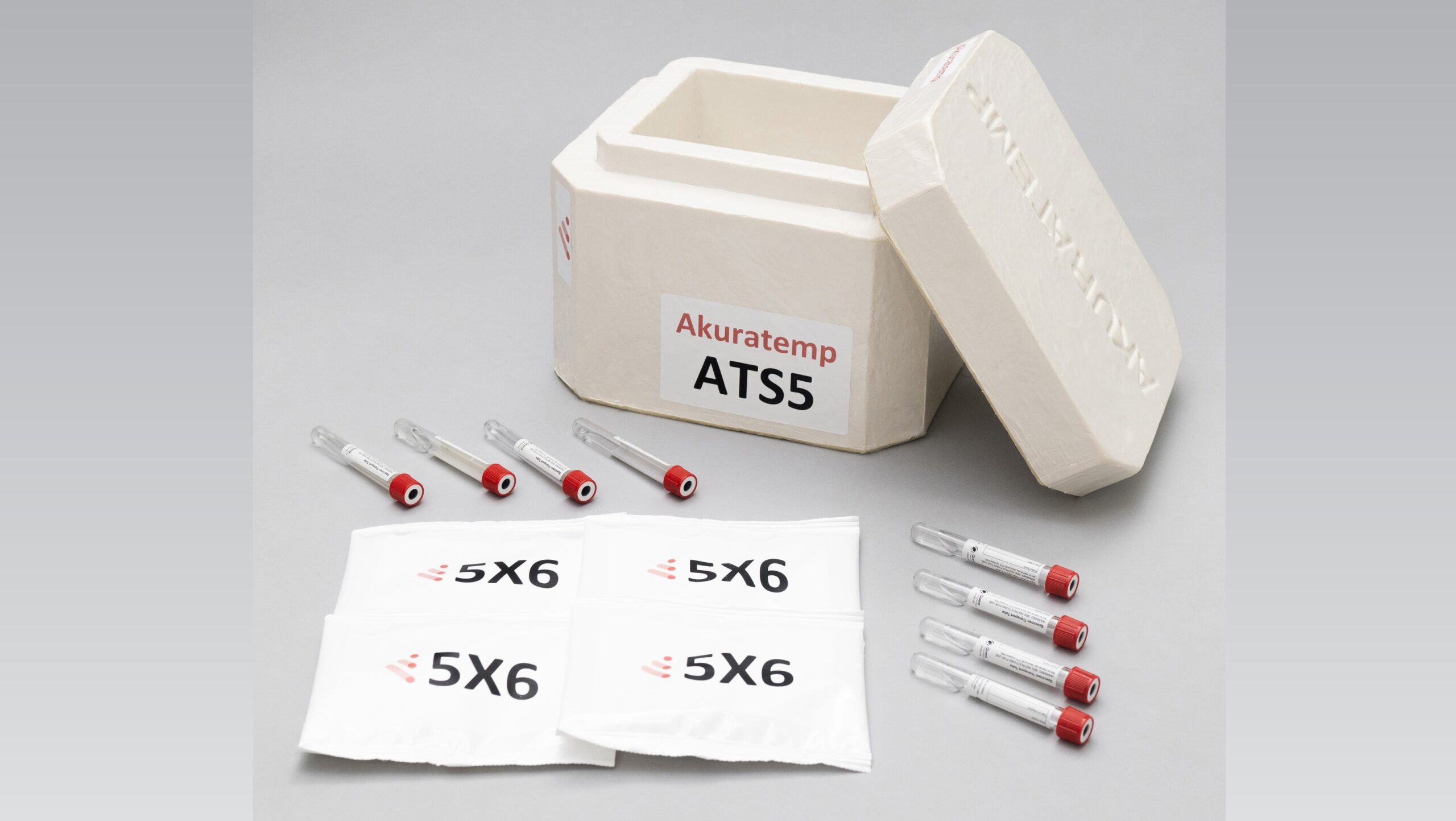

Akuratemp ATS 5

Multi-use sample shipper for 8x10ml vials with 10” x 8.5” x 7.75” external dimensions. Validated per ISTA 7D testing to keep payload between frozen (-15°C to -5°C), refrigerated (+2°C to +8°C), and CRT (+15°C to +25°C).